In an industrial environment, there are two main methods of robot programming online programming (including lead-through and walk-through) and offline programming (OLP). 1 Introduction Although robotics based flexible automation is an intriguing prospect for small to median enterprises (SMEs) in the era of the global competition, the complexity of programming a robotic system remains one of the major implementation challenges. Keywords: offline programming, lean automation, welding, CAD, high DOFs. It takes CAD model as input, and is able to generate the complete robotic welding code without any further programming effort. AOLP is software that automatically plans and programs for a robotic welding system with high Degree of Freedoms (DOFs). This paper presents an automated offline programming (AOLP) method to address this issue. Although robotics based flexible automation is an intriguing prospect for small to median enterprises in the era of the global competition, the complexity of programming remains one of the major hurdles limiting its applications. For further information contact the UOW Library:Ģ Automated Offline Programming for Robotic Welding System with High Degree of Freedoms Zengxi Pan, Joseph Polden, Nathan Larkin, Stephen van Duin, and John Norrish Faculty of Engineering, University of Wollongong, NSW, 2522, Australia Abstract. Lecture Notes in Electrical Engineering, Research Online is the open access institutional repository for the University of Wollongong. Automated offline programming for robotic welding system with high degree of freedoms. Larkin University of Wollongong, Stephen van Duin University of Wollongong, John Norrish University of Wollongong, Publication Details Pan, Z., Polden, J., Larkin, N.

The robot is moved manually, by jogging, to the desired position and the position is saved, teached, in the relative variable.1 University of Wollongong Research Online Faculty of Engineering - Papers (Archive) Faculty of Engineering and Information Sciences 2012 Automated offline programming for robotic welding system with high degree of freedoms Zengxi Pan University of Wollongong, Joseph Polden University of Wollongong, Nathan P.

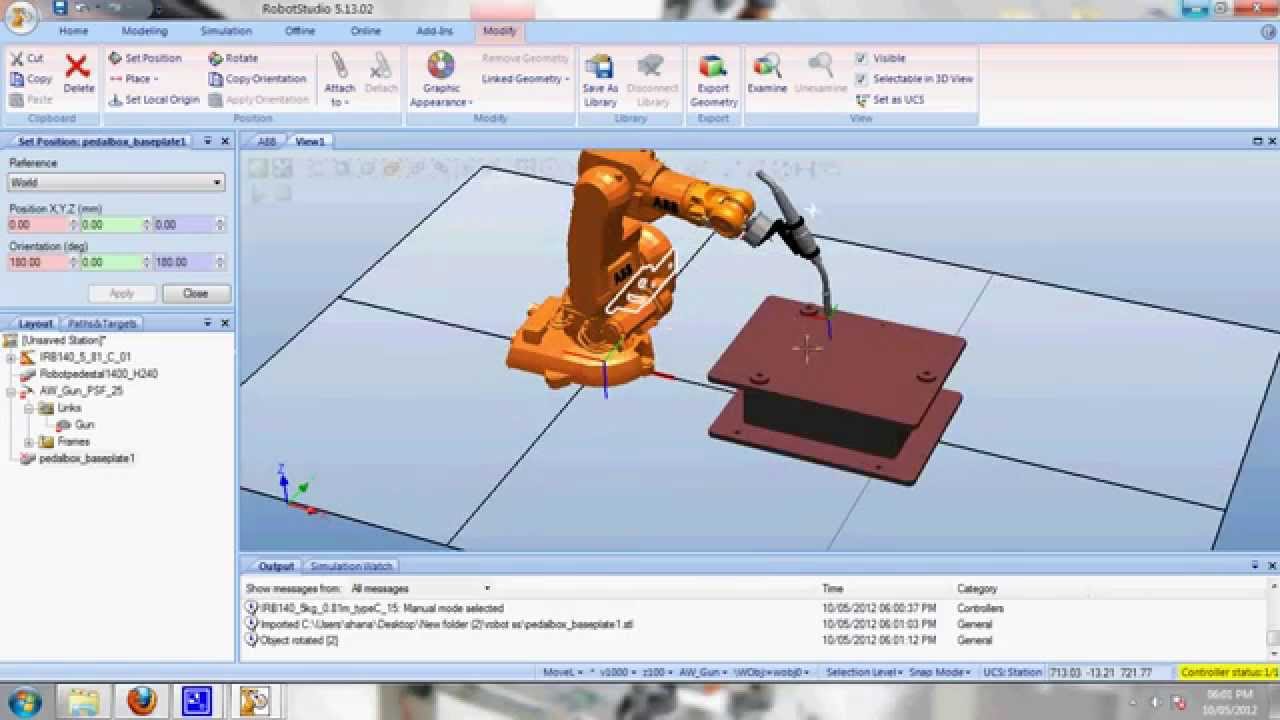

Target positions are Usually taken from mechanical layout, and they don’t match the real ones.ĭuring commisiong the position need to be adjusted. Usually a program is prepared offline, then transferd to a real robot. CONST jointtarget homePos:=,] ĬONST robtarget pos1:=,] ĬONST robtarget pos2:=,]

0 kommentar(er)

0 kommentar(er)